frying machine l potato fryer machine

The automatic fries and potato chips frying production line simplifies and concentrates the production process, and is designed and developed with reference to customer feedback. It has a high degree of automation, saves labor, improves work efficiency, and increases profits for customers.

The automatic fries and potato chips frying production line simplifies and concentrates the production process, and is designed and developed with reference to customer feedback. It has a high degree of automation, saves labor, improves work efficiency, and increases profits for customers.

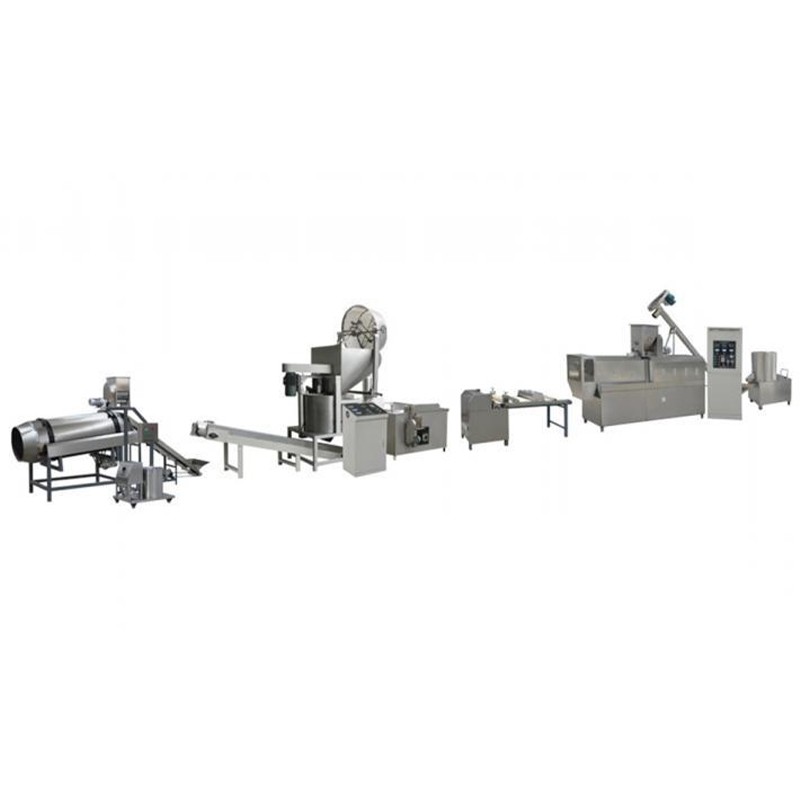

Process flow diagram Clean skin-----slicing and cutting machine-----blanching machine----dehydrator-----frying machine-----de-oiling machine-----seasoning Machine----Vacuum Packaging Machine.

Complete equipment introduction

1. Washing and peeling machine 2. Feeding machine 3. French fries machine 4. Blanching machine 5. Wind blowing and draining 6. Frying machine 7. Wind blowing and draining 8. Packaging machine

1. Cleaning and peeling machine: The brush type cleaning and peeling machine is adopted, which can complete the cleaning and peeling work at the same time. High efficiency and low loss.

2. Strip cutting machine: the strip size can be adjusted from 6mm-10mm.

3. Blanching machine: rinse and protect the color of the cut potato chips (strips).

4. Dewatering machine: dewatering by centrifugal force. Dehydration before frying can greatly shorten the frying time and improve the taste of potato chips.

5. Oil-water mixing fryer: Due to the different proportions of water and oil, the water is below and the oil is heated in the upper layer to make potato chips. The residue produced is directly deposited in the water, and the oil does not emit black smoke, which greatly extends the oil's life cycle. The cost has dropped significantly. The oil temperature is well controlled, thus ensuring the quality and taste of potato chips. After the work is finished, let out the water, and the residue will flow out with the water.

6. De-oiling machine: Centrifugal de-oiling machine de-oils the freshly fried potato chips (strips), which overcomes the defects of high oil content and greasy taste of potato chips (strips). Improve the taste of potato chips (strips).

7. Seasoning machine: The de-oiled potato chips (strips) are seasoned and mixed. The structure is simple and practical. The barrel is designed with stainless steel octagonal shape, which can mix the food materials to be processed with the required seasonings in a short time. Uniform mixing, automatic discharging, convenient cleaning and disinfection, no dead ends.

8. Nitrogen-filled packaging machine: When packaging, fill the packaging bag with nitrogen, which can effectively prevent potato chips (strips) from breaking and prolong the shelf life. Inflation, packaging, and coding can be completed at one time.

A professional after-sales service team will provide you with emergency services, maintenance services, training services and spare parts services.

WhatsApp: +86 15053656233